Milk pasteurization stands as a cornerstone process in the dairy industry, playing a pivotal role in ensuring the safety and quality of dairy products. The primary objective of pasteurization is to eliminate or significantly reduce harmful microorganisms present in raw milk, safeguarding consumers against potential health risks. By subjecting milk to controlled heat treatment, pasteurization effectively targets bacteria, viruses, and other pathogens, curbing their ability to cause illnesses.

Microbial Contamination Challenges in Milk Processing:

The dairy industry faces formidable challenges stemming from microbial contamination during milk processing. Raw milk, sourced directly from farms, can harbor an array of microorganisms that pose health hazards if not adequately addressed.

Bacteria such as Salmonella, Escherichia coli (E. coli), and Listeria monocytogenes are among the concerns, along with other potentially harmful pathogens. These contaminants not only compromise the safety of the end product but also jeopardize the reputation of dairy brands.

Balancing Act in Dairy Production:

The delicate balance between delivering minimally processed, nutrient-rich dairy products and ensuring consumer safety is a constant challenge. Meeting stringent hygiene standards while preserving the nutritional value of milk requires sophisticated processing technologies. In this context, milk pasteurization emerges as a vital step, striking the right equilibrium by eradicating harmful microbes without compromising the essential qualities of the dairy products.

As we delve into the nuances of milk pasteurizers, it becomes evident how these technological solutions address the pressing challenges of microbial contamination, contributing to the production of safe and high-quality dairy items for consumers worldwide.

In the subsequent sections, we’ll continue to expand on Economy’s milk pasteurizers, delving into their unique features, applications, and the overall benefits they bring to the dairy processing industry.

II. Understanding the Battle Against Microbial Contamination

Milking Down the Microbes:

Microbial contamination poses a significant challenge in the dairy industry, with various types of microorganisms seeking refuge in milk. Bacteria, yeasts, molds, and pathogens can compromise both the quality of dairy products and the health of consumers. Understanding these potential contaminants is crucial in fortifying the dairy processing journey against microbial invaders.

Impact on Dairy Product Quality and Consumer Health:

The invasion of microorganisms in milk can lead to a cascade of detrimental effects. Beyond altering the taste, texture, and smell of dairy products, microbial contamination can compromise their nutritional content.

Moreover, certain pathogens can pose serious health risks to consumers. Recognizing the potential consequences underscores the importance of adopting stringent measures to ensure the microbial purity of dairy products.

Economy’s Milk Pasteurizers: Ensuring Safe and Quality Dairy Products

Economy Solutions takes center stage in the battle against microbial contamination with its lineup of advanced milk pasteurizers. These machines are designed to be the frontline defenders, equipped to thermize, pasteurize, and precisely control the heating and cooling processes for a spectrum of dairy products. The pasteurizers act as sentinels, ensuring that every drop of milk undergoes the necessary treatment to eliminate harmful microorganisms.

Key Features and Specifications:

Delving into the arsenal of features, Economy’s milk pasteurizers are armed with a system of probes dedicated to achieving impeccable pasteurization. This not only guarantees the elimination of microbes but also ensures that the process is perfect and precise. The machines are available in manual, semi-automatic, and automatic versions, providing operational flexibility to dairy processors.

Customization for Various Dairy Processing Applications:

Recognizing the diverse landscape of the dairy industry, Economy Solutions tailors its pasteurizers to suit various processing needs. The customizable flow rates empower clients to adapt the pasteurizers to their unique operational requirements. This adaptability is a testament to Economy’s commitment to providing solutions that align with the specific challenges posed by different dairy processing applications.

In the relentless battle against microbial contamination, Economy Solutions’ milk pasteurizers stand tall as guardians of dairy product safety and quality. With advanced features, precise controls, and a commitment to customization, these pasteurizers ensure that every dairy product emerging from the processing line is not just dairy – it’s a promise of purity, safety, and uncompromised quality.

Efficient Microbial Contamination Management: The Pasteurization Process

In the relentless pursuit of ensuring dairy product safety, Economy Solutions’ milk pasteurizers employ sophisticated pasteurization techniques. These techniques involve subjecting milk to specific temperatures for precise durations, effectively eliminating harmful microorganisms. Whether it’s thermizing, pasteurizing, or regulating heating and cooling, these techniques are pivotal in creating a dairy processing environment that upholds the highest standards of microbial purity.

Role of Milk Pasteurizers in Eliminating Harmful Microorganisms:

At the core of microbial contamination management, milk pasteurizers play a pivotal role in neutralizing potential threats. The systematic application of heat ensures that bacteria, yeasts, molds, and other contaminants are eradicated, preserving not just the safety but the integrity of dairy products. Economy Solutions’ pasteurizers act as stalwart guardians, ensuring that each dairy product undergoes a meticulous microbial cleansing.

Real-world Applications and Success Stories:

Beyond theory lies the real-world impact of Economy Solutions’ milk pasteurizers. Numerous success stories and applications across the dairy industry stand testament to the efficacy of these machines. From ensuring the safety of milk to the production of a spectrum of dairy products, the pasteurizers have been instrumental in elevating the standards of microbial contamination management.

Benefits of Milk Pasteurizers in Dairy Processing

Preservation of Milk Quality and Flavor:

The primary goal of pasteurization is not just the elimination of microorganisms but the preservation of milk quality and flavor. By eradicating contaminants, milk pasteurizers ensure that the inherent characteristics of milk are retained, delivering a final product that not only meets safety standards but also delights consumers with its freshness and taste.

Compliance with Dairy Industry Standards and Regulations:

In an industry governed by stringent standards, Economy Solutions’ milk pasteurizers stand as compliant custodians. These machines adhere to and often surpass dairy industry regulations, ensuring that every dairy product emerging from the processing line is not just safe for consumption but aligns with the highest quality benchmarks.

Application in Various Dairy Product Manufacturing Stages:

Versatility is a key attribute of Economy’s milk pasteurizers. From the initial stages of thermizing to the final steps of cooling, these machines seamlessly integrate into various dairy product manufacturing stages. Whether it’s the production of milk, curd, yogurt, or other dairy derivatives, the pasteurizers contribute to the creation of safe, high-quality products.

In the dynamic landscape of dairy processing, Economy Solutions’ milk pasteurizers emerge as beacons of efficient microbial contamination management. Through advanced techniques, real-world applications, and a myriad of benefits, these pasteurizers redefine the standards of purity, safety, and excellence in the dairy industry.

Innovation in Pasteurization Technology

Advanced Features Enhancing Pasteurization Precision:

In the pursuit of continual improvement, Economy Solutions integrates cutting-edge features into its pasteurization technology. These advancements are designed to enhance precision, offering more nuanced control over the pasteurization process. Whether it’s precise temperature regulation, automated monitoring, or adaptive controls, these features contribute to elevating the accuracy and efficiency of the pasteurization technology.

Integration with Industry-Specific Processes:

The dynamism of the dairy industry demands solutions that seamlessly integrate with industry-specific processes. Economy Solutions’ pasteurization technology is not just a standalone system but a harmonious component within the broader spectrum of dairy processing. From milk to yogurt, each facet of the industry’s unique processes is considered and accommodated, ensuring a cohesive and efficient operation.

Ensuring Operational Efficiency and Dairy Product Safety

Routine Maintenance Guidelines:

Operational efficiency and safety are intrinsically linked to the regular maintenance of pasteurization equipment. Economy Solutions provides comprehensive guidelines for routine maintenance, empowering dairy processors to uphold the longevity and performance of their pasteurizers. Regular checks, timely replacements, and adherence to maintenance protocols become the pillars supporting the continued efficiency of the equipment.

Monitoring and Optimization for Continuous Results:

Continuous results require continuous monitoring and optimization. Economy Solutions’ pasteurization technology incorporates intelligent monitoring systems that allow dairy processors to track and optimize the pasteurization process in real-time. This not only ensures consistent results but also provides the flexibility to adapt to varying production demands, contributing to operational efficiency.

In conclusion, Economy Solutions’ commitment to innovation, operational efficiency, and real-world impact is evident in its pasteurization technology. From advanced features to seamless integration, routine maintenance guidelines to real-world success stories, this technology stands as a testament to the company’s dedication to redefining standards in the dairy processing landscape.

As the industry evolves, Economy Solutions remains at the forefront, delivering not just pasteurization equipment but comprehensive solutions that propel the dairy sector towards excellence.

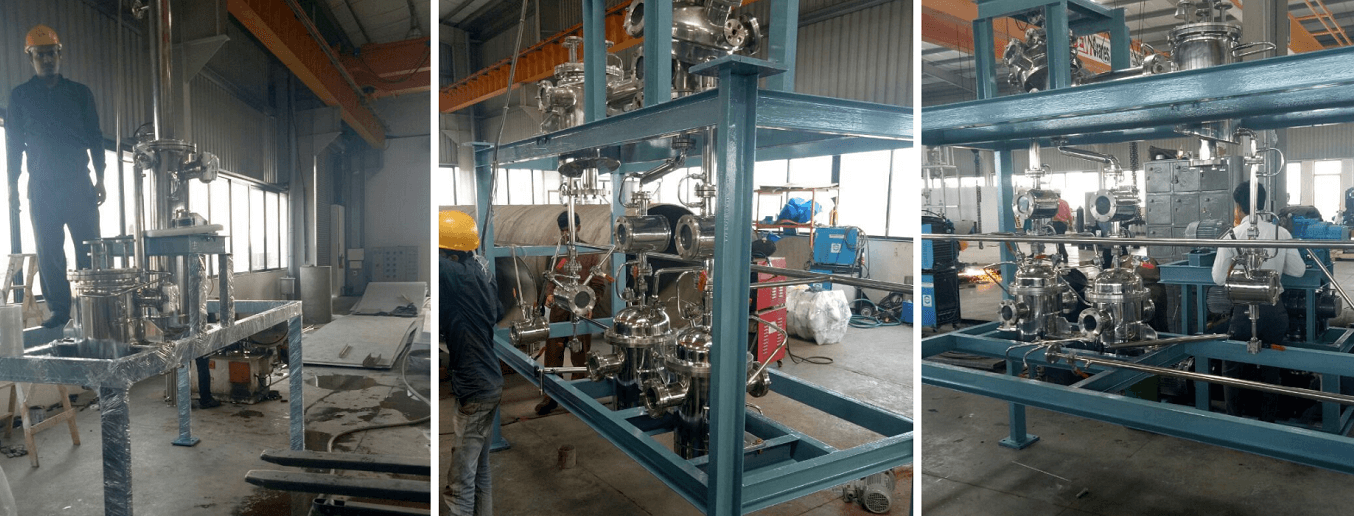

Pilot Plant Facility

Experience advanced pilot plant facility for testing and refining processes with state-of-the-art equipment and expert support