Table of Contents

Winemaking, an art that transforms grapes into a symphony of flavors, demands precision at every step to create a product that delights the senses. Central to this craftsmanship is the imperative of maintaining consistent quality throughout the winemaking process. Each sip of wine should reflect the essence of the grapes and the meticulous care taken during production.

At Economy Process Solutions, we understand that the pursuit of perfection in winemaking requires reliable and innovative solutions. Our commitment is unwavering — to deliver high-quality winemaking process solutions that elevate the industry standards and contribute to the creation of exceptional wines.

Winemakers face an array of challenges that significantly impact the quality of the final product. Filtration, lees separation, and clarity improvement stand out as crucial stages where precision is paramount. Filtration challenges arise in the removal of impurities, ensuring that the wine retains its purity and character. Lees separation, dealing with sediment and unwanted particles, is critical for maintaining the wine’s integrity and preventing undesirable flavors. Clarity improvement becomes essential for enhancing visual appeal and overall aesthetics.

These challenges are not mere technicalities; they are the intricacies that can make or break a bottle of wine. Inconsistent filtration might leave unwanted residues, affecting taste and mouthfeel. Poor lees separation can result in murky wines, undermining both visual appeal and quality. Clarity improvement, neglected or executed poorly, might compromise the overall presentation of the wine.

Understanding the impact of these challenges is pivotal for winemakers. A deviation from the desired standards at any stage can cascade into a series of issues affecting taste, aroma, and appearance. It is at these critical junctures that Economy Process Solutions steps in, providing cutting-edge solutions to overcome these challenges and uphold the essence of winemaking. Our commitment is not just about addressing problems; it’s about elevating the winemaking journey to new heights, where consistency is not just a goal but a guarantee.

Section 2: Rotary Vacuum Filters – Ensuring Efficient Filtration:

Rotary Vacuum Filters stand as the pinnacle of efficiency in the winemaking filtration process. These filters are engineered to execute thorough and effective filtration, ensuring that the final product meets the highest standards of clarity and purity. The design of Rotary Vacuum Filters is meticulously crafted to handle a diverse range of products, including wine, with a continuous cycle operation. This operational mode ensures a seamless and uninterrupted filtration process, maximizing efficiency.

Rotary Vacuum Filters employ a robust construction, primarily built from stainless steel, ensuring durability and longevity in the demanding winemaking environment. The continuous cycle operation is a testament to the precision engineering incorporated into these filters. They efficiently handle a continuous inflow of wine, maintaining a consistent and high throughput. This adaptability is vital for winemakers dealing with varying volumes and production demands.

Section 3: NDC Crusher Destemmer – Preserving Grape Quality:

The NDC Crusher Destemmer is a technical marvel designed to address a critical stage in winemaking – the separation of grapes from stems while preserving grape quality. Engineered with a focus on precision, this equipment ensures that the essential flavors and characteristics of the grapes remain intact throughout the crushing and destemming process.

User-friendly features are embedded in the NDC Crusher Destemmer, simplifying operations for winemakers. The design prioritizes efficiency without compromising on grape quality. The range of models available caters to the diverse production needs of winemakers, providing flexibility and scalability. This adaptability is fundamental for both small and large-scale wineries, allowing them to integrate this equipment seamlessly into their unique production processes.

Section 4: Discharged Kieselgur Filters – Improving Brightness and Finishing:

The Discharged Kieselgur Filters epitomize innovation in winemaking, particularly in the quest for improved brightness and finishing. The exclusive horizontal disk system employed by these filters sets them apart in the industry. This system ensures a level of precision and effectiveness that contributes significantly to the filtration of wines and lees.

The horizontal disk configuration is designed to maintain the integrity of the filtration cake even during intermittent interruptions, guaranteeing a consistent and reliable filtration process. The quick and straightforward cake discharging, emptying, and cleaning mechanisms reduce downtime for servicing, enhancing overall operational efficiency.

In essence, the Discharged Kieselgur Filters provide winemakers with a tool that goes beyond conventional filtration, actively contributing to the enhancement of the visual and gustatory qualities of the final wine product.

Section 5: Ecoflot Batch Flotators – Clarifying Grape Must:

In the process of winemaking, the Ecoflot Batch Flotators emerge as a pivotal solution for clarifying grape must during pumping-over. These flotators play a crucial role in ensuring the purity and clarity of the grape must, a fundamental step in the production of high-quality wines.

The Ecoflot Batch Flotators leverage the use of adjuvants such as bentonite, gelatin, or silica sol to break down the colloidal structure of the must. This strategic approach facilitates the removal of impurities and unwanted particles, contributing to the overall clarity and purity of the grape must. The versatility of the Ecoflot Batch Flotators allows winemakers to tailor the clarification process to meet specific requirements, adding a layer of customization to the winemaking journey.

Wepresent Della Toffola Industrial Plate Filters as part of our comprehensive winemaking solutions. These filters stand as a pinnacle of effectiveness, simplifying the intricate task of filtering lees, wines, must, and other winemaking byproducts. Manufactured by Della Toffola, our Industrial Plate Filters embody a robust design founded on proven technology, ensuring operational simplicity while delivering highly efficient separation of liquids from solids.

Our filters go beyond the conventional by not only separating liquids but also recovering valuable liquid content still present in the lees. They excel in producing solid cakes rich in material, suitable for utilization across various industries. Crafted with top-quality materials, these filters boast durability and reliability, making them an ideal long-term solution for winemaking processes.

In addition to their durability, the components in direct contact with the product are crafted from AISI 304 stainless steel, ensuring high hygiene standards. The comprehensive design includes a feed pump and a hydraulic system for manual or automatic filter closure. The industrial filter press pack features plastic plates with a central manifold for uniform product distribution and corner manifolds for efficient filtrate collection. Each filter plate is equipped with a sheet of polypropylene fabric, contributing to the overall efficiency of the filtration process.

The versatility of Della Toffola Industrial Plate Filters extends beyond winemaking, making them suitable for diverse industries, including Pharmaceuticals, Chemicals, Food Products, Beverages, and more. Furthermore, they find applications in non-food sectors like paint. For businesses seeking reliable and efficient filtration solutions, our Della Toffola Industrial Plate Filters stand as a testament to engineering excellence. Contact us today to explore how these filters can elevate your winemaking and industrial processes.

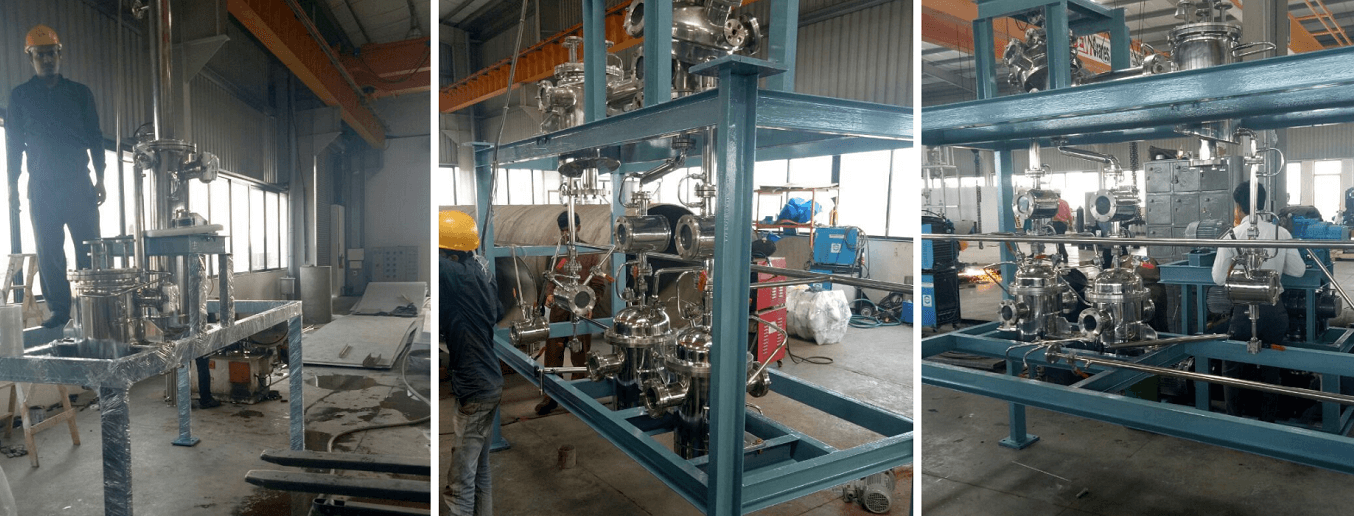

Pilot Plant Facility

Experience advanced pilot plant facility for testing and refining processes with state-of-the-art equipment and expert support